Why Panel PCs Are Perfect For Industrial Applications?

The rugged all-in-one package appeals to a wide range of industries.

In recent years, a significant shift has taken place in industrial computing. Panel PCs have gradually been replacing their bulky predecessors, to the point where they’re now involved in most production processes. Among the most common applications are real-time feedback, control and monitoring of production lines, and client stations for video surveillance systems.

But what is it that makes them so popular?

Designed for seamless installation into industrial environments, panel PCs offer simple integration with existing production line architecture, such as control cabinets, machines, kiosks and similar.

Panel PCs are often used as Human-Machine Interfaces (HMI). The hardware’s ruggedness ensures strong durability in challenging conditions, and the machine’s inbuilt touchscreen gives the operator easy access to vital data.

Panel PCs thrive in a host of different industrial scenarios. Among the most common applications are:

- Original Equipment Manufacturer machinery (OEM)

- Human-Machine Interface (HMI)

- Machine-to-Machine Interface (M2M)

- Control and data aggregation in relation to Internet of Things (IoT)

- Vision systems

- Factory automation systems

- Materials handling

Significantly more durable than standard PCs

There are many reasons to choose panel PCs for your next project, whether you’re concerned with inventory control, industrial- and automation control, or logistics.

One of the key benefits of industrial-grade panel PCs is the durability. Constructed for the demanding industrial conditions, they are made with robust, long-life components, and offer good backward compatibility.

Should you instead choose a non-industrial panel PC, certain components in your configuration might become obsolete within a couple of years. There’s also the risk that replacement components have different specifications. But if you opt for an industrial solution, you can expect a lifespan of 5–7 years. This naturally makes finding spare parts much easier.

Industrial panel PCs not only last longer than their office- and domestic siblings, but also perform better in rough conditions. Their temperature tolerance is higher, which translates to reduced downtime and increased productivity.

Standard portable and stationary computers deteriorate with frequent use. Industrial panel PCs have highly robust exteriors to protect the internal components and ensure reliable operation for the long haul.

6 benefits of panel PCs

Touch boosts productivity

The touchscreen replaces keyboard and mouse. By keeping your eyes on the task at all times, you can work faster and make fewer input errors.

Designed for easy cleaning

Panel PCs are designed to handle a good scrub – a must for coping with unclean environments or strict regulatory hygiene standards.

They are versatile

Panel PCs can be installed almost anywhere and be used for all kinds of industrial applications.

Most are fanless – and dustless

Dust is a stubborn adversary. Many Panel PCs have fanless cooling systems, which means no dust enters the internal parts.

Built for harsh conditions

Industrial environments can be extremely demanding. Touchscreen Panel PCs are built with rugged materials and inbuilt protection mechanisms.

Made to adapt

Nothing is set in stone with a Panel PC. You can easily configure them as you please, for anything from basic functionality to complex tasks.

Blog Posts

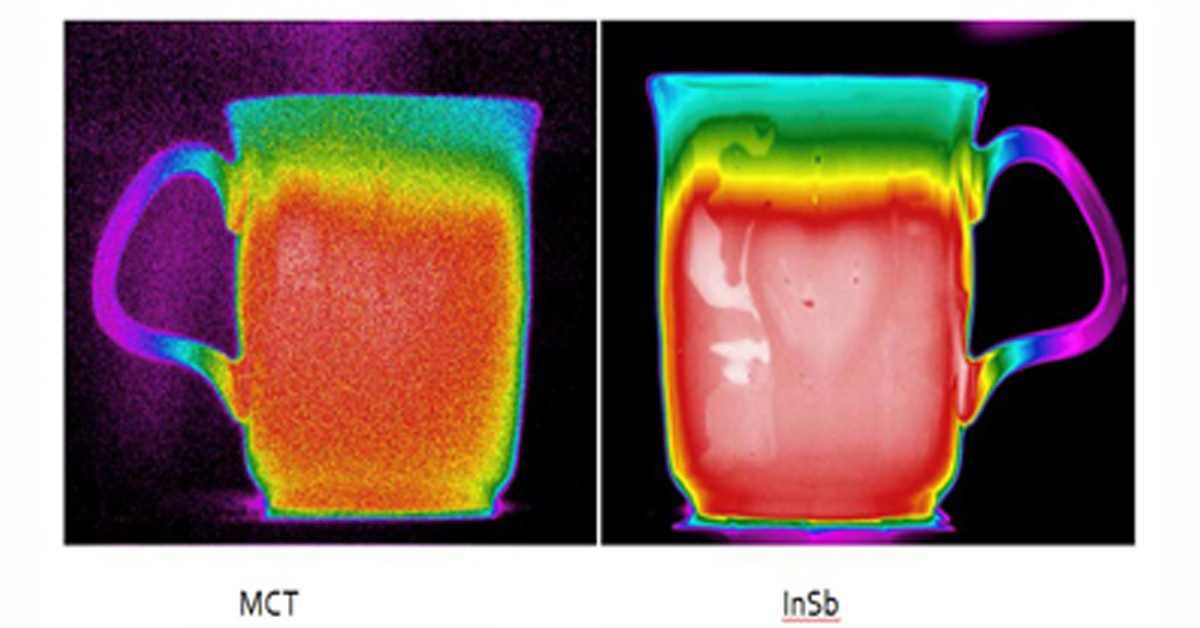

Thermal Camera Selection

How Far Can I See?

How Should Human Temperature Be Measured?

What is Wide Dynamic Range?

MYNOISE AUDIO MIXER REVIEW

WHAT IS A WIRELESS DISTRIBUTION SYSTEM?

POE VS. POE+ VS. POE++: CHOOSING THE RIGHT INDUSTRIAL ETHERNET SWITCH FOR YOU

INDUSTRY-LEADING INDUSTRIAL ETHERNET SWITCHES

UNDERSTANDING WHAT THE INDUSTRIAL INTERNET OF THINGS IS

THE DIFFERENCE BETWEEN A HUB, SWITCH, & ROUTER

5 Benefits of Thermal Imaging Cameras

DIFFERENCE BETWEEN INDUSTRIAL ETHERNET AND REGULAR ETHERNET

INDUSTRIAL NETWORKING EQUIPMENT USED FOR AUTONOMOUS VEHICLES

CYBERSECURITY: PROTECTING INDUSTRIAL CONTROL SYSTEMS

HOW INDUSTRIAL NETWORKING CAN PROVIDE SECURITY FROM DRONES

.webp)

Thermal Cameras Reveal How to Keep Your Home Cool During a Heat Wave

FLıR ONE PRO

.png)

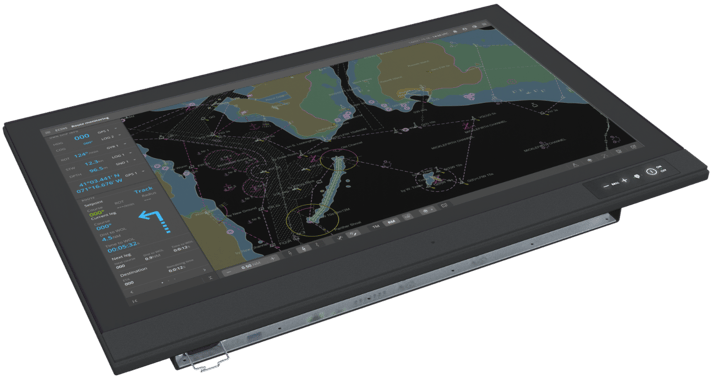

Unmatched Maritime Awareness with Cooled Thermal Imaging

.png)

What Is the Right Handheld Thermal Camera for You?

.png)

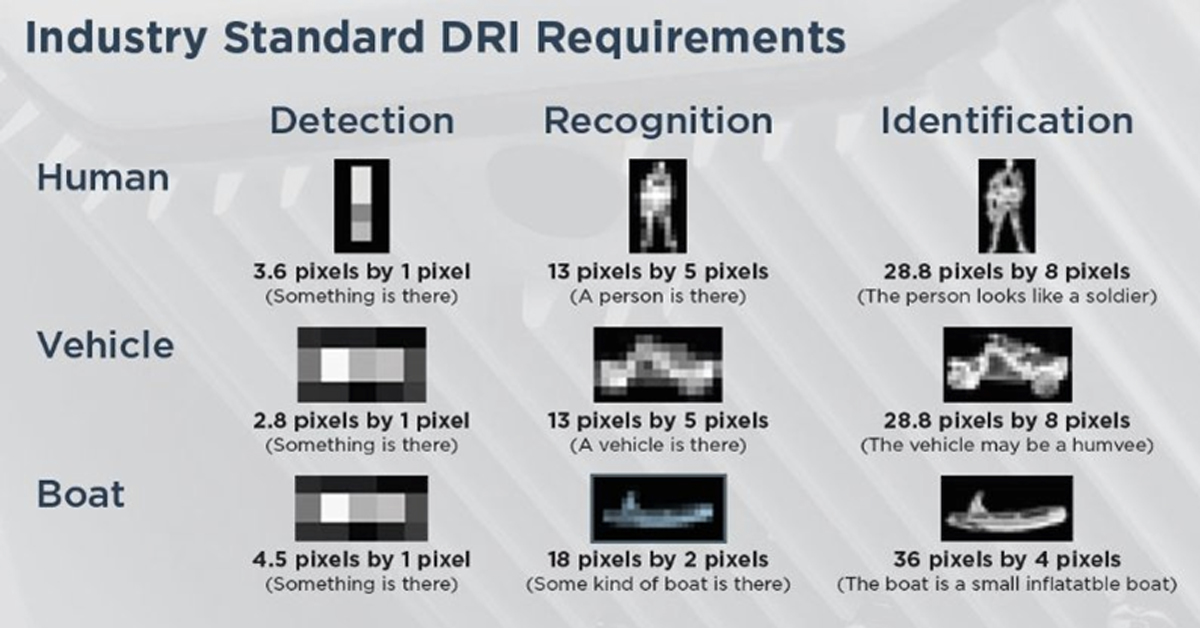

Camera Resolution and Range

.png)

Special Applications for Marine Cameras

.png)

What’s The Difference between Thermal Imaging and Night Vision?

.png)

Can Thermal Imaging See Through Fog and Rain?

Which Cx-Series Camera Is Right for You?

.png)

What is MSX®?

Five Reasons Maritime First Responders Need Thermal Imaging

.png)

3 Distinguishing Features of Superior Thermal Cameras

.png)

Determine Which Visible and Thermal Security Cameras You Need

Bullet vs. PTZ vs. Dome: Which Security Camera Is Right for You?

Interfaces for Machine Vision

Machine Vision Sensor Review

.png)

Teledyne FLIR, the Industry Leader, Launches Boson +, a Long-Wave Infrared Thermal Imager Module with an Accuracy of Less Than 20 mK

.png)

Whitepaper: IP-Based Security Convergence

.png)

3 Technologies Transforming Safe Cities into Smart Cities

.png)

Insights from the Field: Ensuring Workplace Safety Using Thermal Camera Screening for Entry Control

Thermal Night Vision as a Force Multiplier

Can Thermal Imaging See Through Walls? And Other Common Questions

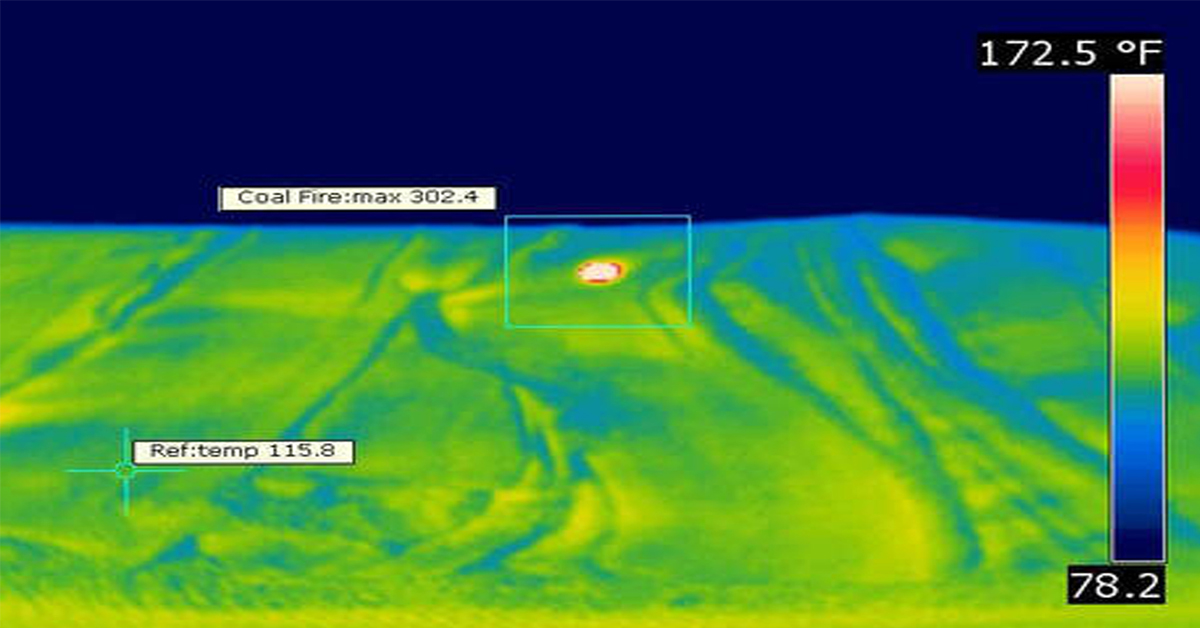

Application Spotlight: Early Fire Detection for Rapid Heat Generation

Protect Personnel and Equipment by Detecting Early Signs of Fire

Teledyne FLIR Launches A500f/A700f Cameras for Fire Detection and Condition Monitoring

Thermal Imaging Cameras Help Guarantee Fire Safety in Tunnels

Thermal Imaging Cameras Help to Prevent Fires

ITS-Series Dual AID Surpasses Standards for Fire Detection Systems in Japan

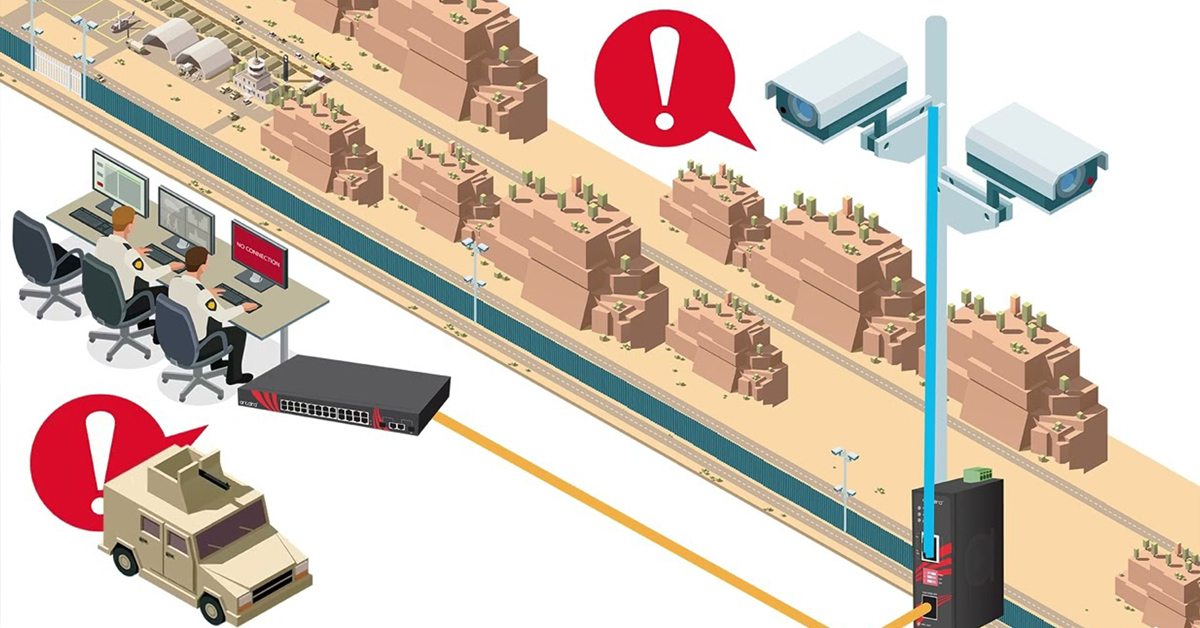

How Layering Multispectral PTZ Cameras and Radars Improve Perimeter Protection

POWER REMOTE RESET TECHNOLOGY - PRRT

Why Yacht Owners are Adding Thermal Imaging Cameras to Minimise the Risk of Lithium-Ion Battery Fires?

.png)

Intelligent Transportation Systems

Best Practices Guide for Perimeter Security Applications

Protect Pedestrians, Bicyclists and More with Thermal Smart Sensors

White Paper: Application of Ground-Based Security Radar to Perimeter Systems

What is Thermal Leakage and How to Reduce Its Risks

Battery Inspection Using Advanced Thermography

Providing ire Protection for Lithium Battery Storage

The Power of Thermal Imaging

.png)

Why Panel PCs Are Perfect For Industrial Applications?

Teledyne DALSA

.png)

Advantages of Virtual Barrier Video Analytics for Perimeter Security Systems

.png)

.png)

NASA Takes the Teledyne FLIR Boson Thermal Camera Module Out of this World

.png)

Port Security Enhancement: DP World Yarımca's Trust in FLIR Security Solutions for Effective and Safe Port Operations

.png)

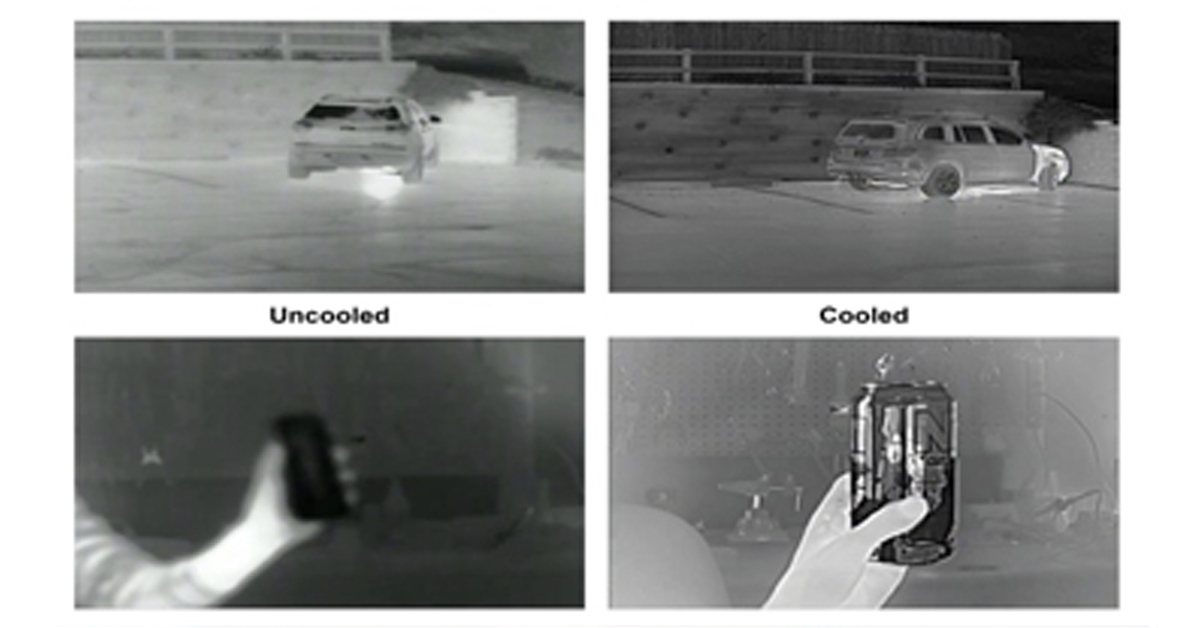

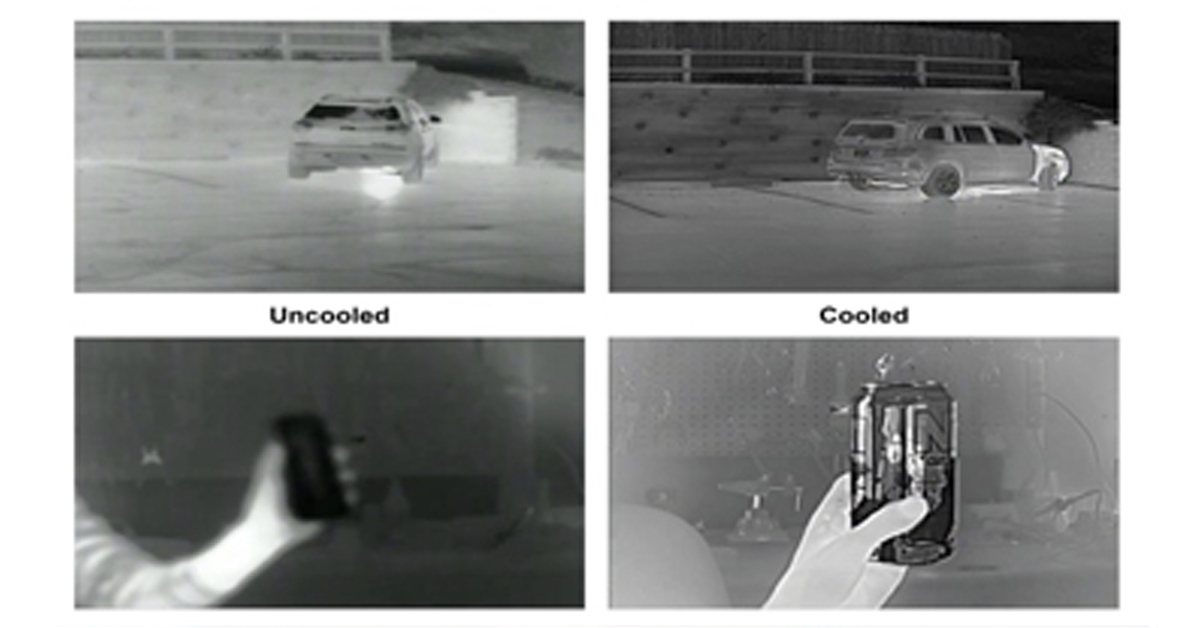

The Importance of Thermal Sensitivity (NETD) for Detection Accuracy

.png)

Bosphorus Boat Show 2025: The Meeting Point of the Maritime World

Application Spotlight: Critical Asset Monitoring for Thermal Conditions

.png)

Thermal Imaging for Marine Firefighting

Imaging in Mobile Mapping

.png)

Using Thermal Imaging for Oil Spill Detection

Five Reasons Maritime First Responders Need Thermal Imaging

Case Study: Tackling Compressed Air Leaks in Automotive Parts Manufacturing with Acoustic Imaging

Thermal Night Vision as a Force Multiplier

.png)

Line Scan Contact Image Sensor - AxCIS

Beyond Resolution: What Really Makes a Camera System Work for Mobile Mapping

.png)

Multispectral Marine Cameras for USV Applications

.png)

Stabilizing FLIR Cameras for Smooth Viewing in Rough Waters

(1).png)